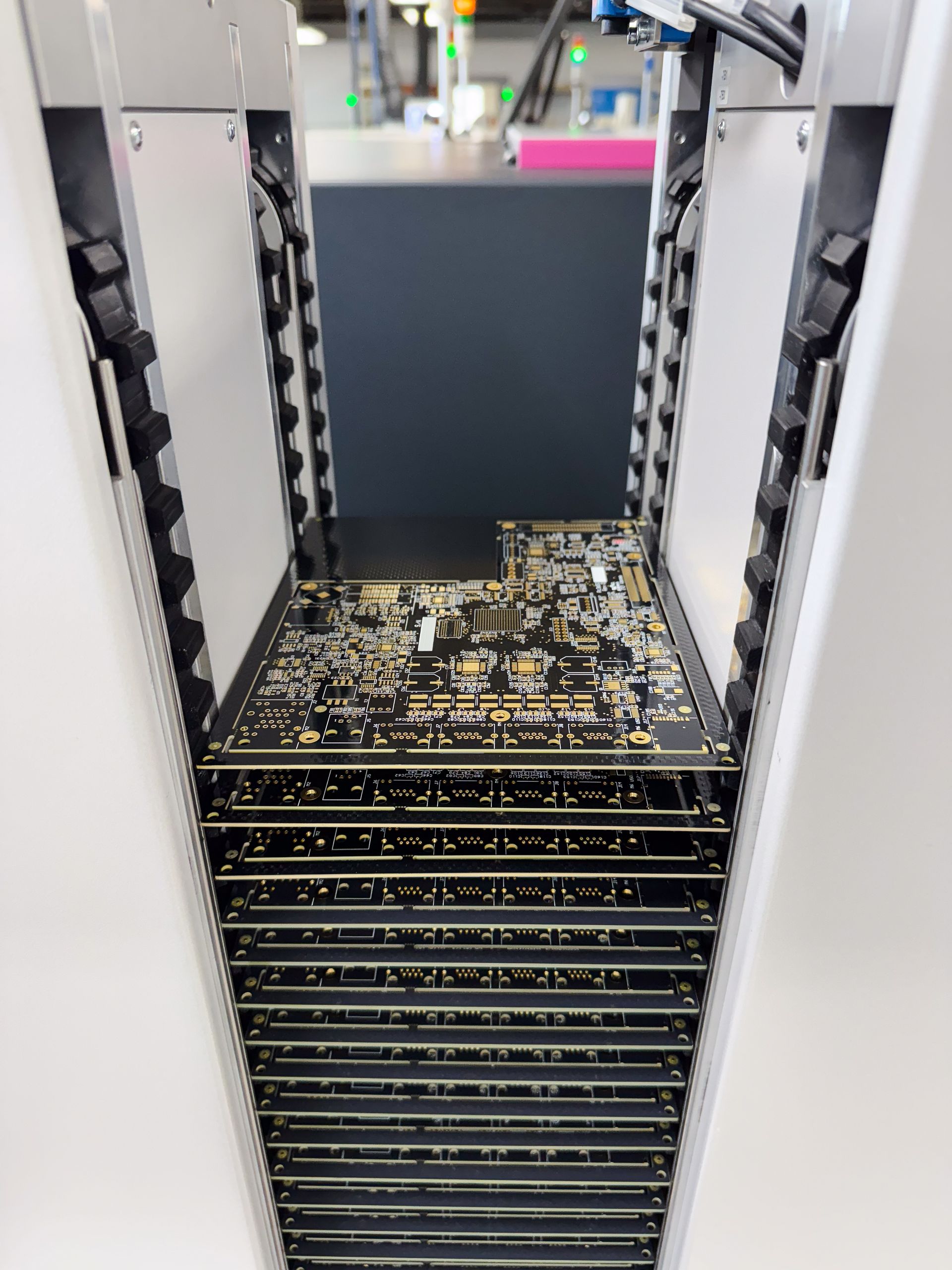

PCB Inventory Management

Reduce lead times, lower costs, & ensure availability with our PCB stocking program

Keep production on track with ETEMCO

Our expert team utilizes our ERP System to manage your product inventory via our efficient stocking program. We work with you to set safety stock and production order quantities so that we can proactively monitor inventory levels to prevent stock-outs, minimize downtime, and save you money.

Prevent component shortages

Material shortages and stock-outs can kill production efficiency for both you and us. With our advanced MRP system, we effectively manage our supply chain and stay ahead of demand so we can deliver what you need, when you need it.

Reduce lead times with pre-stock

We make sure vital materials and components are on hand when you need them. By maintaining a well-organized stock of supplies, we eliminate delays and keep your production process running smoothly. This way, you’re able to meet tight deadlines and boost overall efficiency.

Secure pricing against market fluctuations

Lock in pricing to combat market variations so you don’t have to worry about unexpected price hikes. With our smart inventory management and strong supplier relationships, we help keep your costs steady so you can focus on what matters without the stress of price changes.

Release inventory based on demand

Adjust inventory levels according to demand to keep your stock in line with what your customers need. By closely tracking customer demand and tweaking inventory levels accordingly, we help you avoid wasting space and excess inventory. This means lower storage costs, faster turnaround times, and a better ability to fulfill orders right when customers want them.

Just-in-time (JIT) inventory — Get PCBs when you need them

Flexible inventory solutions

The strategy we’ve found most efficient is only to stock what’s needed for immediate demand, minimizing storage costs and improving cash flow. We don’t stockpile products and ensure that inventory stays lean, which lets us quickly adapt to customer needs without tying up resources in excess stock.

Seamless PCB inventory management from order to delivery

How our stocking program works

Assess inventory needs & forecasted demand

We start by evaluating your current inventory levels, production schedules, and customer demand trends. By looking at data from previous months and predicting future needs, we’ll make sure things align with upcoming demand, preventing both overstocking and stock-outs.

Establish a stocking agreement based on your usage

We collaborate with you to create an individualized stocking agreement that reflects your specific usage patterns and business needs. Following this technique means that the right amount of inventory is available to meet demand while also providing flexibility to adjust as your usage changes over time.

ETEMCO stocks & manages your PCB assemblies or components

With our stocking program, you have the flexibility to receive your materials exactly when you need them. With scheduled releases, you’ll get a steady supply of components at regular intervals, while our JIT fulfillment allows you to avoid overstocking by delivering inventory only when your demand requires it.

Scheduled releases or just-in-time (JIT) fulfillment

With our stocking program, you have the flexibility to receive your materials exactly when you need them. With scheduled releases, you’ll get a steady supply of components at regular intervals, while our JIT fulfillment allows you to avoid overstocking by delivering inventory only when demand peaks.

Common questions about PCB inventory management

How does ETEMCO’s stocking program help reduce lead times?

Lead-times are reduced to almost nothing because your product is on the shelf when you need it. Place an order and have your boards within days.

What are the benefits of ETEMCO's stocking program?

The most obvious one is reduction of lead-times, but also pricing is based on the stocking agreement quantities, which allows for lower costs. Another benefit is it allows for fluctuation in demand, both positive and negative.

Can I adjust my stocking agreement based on demand changes?

Yes, the stocking agreement can be adjusted as needed, and that includes quantities, pricing, terms, etc.

What types of PCBs and components can ETEMCO stock for customers?

We stock all kinds of PCB assemblies as well as hard-to-find or long lead-time components that support your final assembly.

How do I get started with a PCB stocking agreement?

Just let us know you are interested. We will be happy to walk you through the process and explain your options.

Get started with a PCB stocking program at ETEMCO

Fast quotes, responsive service, & forward-thinking production

Focus on your day-to-day operations and let us at ETEMCO handle the inventory management for your printed circuit boards. By using a sophisticated MRP system to maintain stock levels, you can rest assured knowing that critical components are always readily available. We take control of your inventory so you don’t have to.

Contact us today for more information about how our solutions can benefit your business and streamline your processes.