Telecom PCB Assembly for High-Frequency Communication Systems

Precision Telecom PCBs Built for Reliable Signal Transmission and Continuous Data Exchange

What It Takes to Build Telecom PCBs You Can Trust

When communication systems go down, the impact is immediate. Data stops moving. Networks fail. Entire operations feel it at once. Telecom PCB assembly isn’t just about building a board. It’s about protecting the systems people rely on every day.

At

ETEMCO, we support telecom OEMs who can’t afford noise, drift, or inconsistency in their telecom boards. Our ISO 9001-certified processes, U.S.-based manufacturing, and disciplined build controls help you reduce risk, maintain performance, and move from design to deployment with confidence.

What Telecom PCB Assembly Requires — and Why It’s Different

Telecom hardware operates continuously in environments that change. If a telecom circuit has weaknesses, they often surface after deployment, when downtime is expensive and fixes aren’t simple.

That’s why telecom PCB assembly can’t be treated like general electronics manufacturing. The margin for error is smaller.

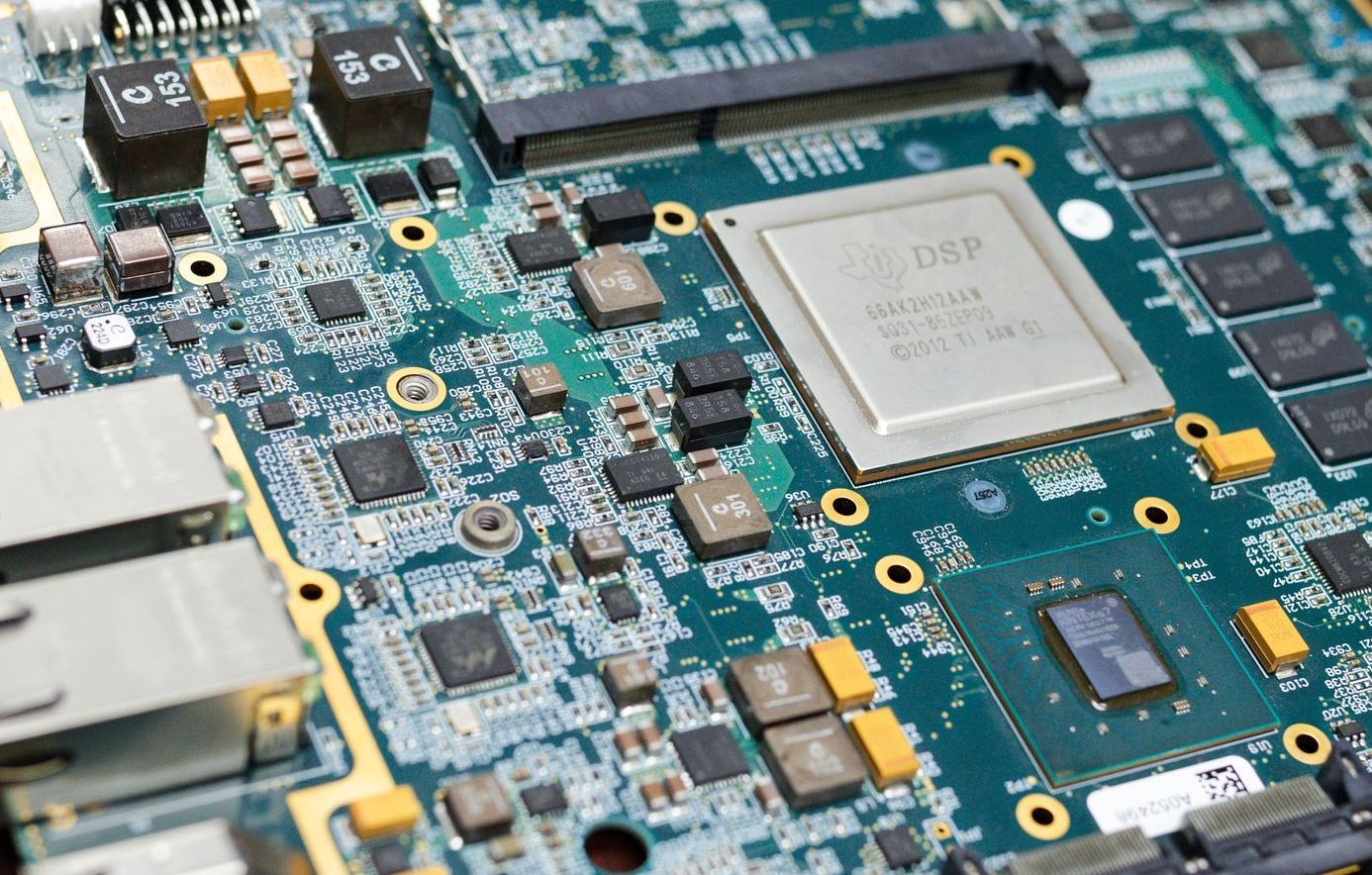

High-Frequency Signals Demand Precision Assembly

High-frequency PCB communication circuits amplify small assembly mistakes. Variations in trace width, component placement, or solder volume can disrupt impedance matching and signal transmission, even when a board looks fine.

We control those risks through consistent SMT placement, disciplined soldering processes, and inspection methods designed for high-frequency applications. AOI and X-ray inspection help catch issues early, before signal problems appear in live systems.

Communication Systems Can’t Tolerate Signal Loss

In telecom environments, even brief signal degradation can create cascading problems across connected systems. These communication applications can’t tolerate a signal

loss, noise, or timing issues:

- Core network infrastructure — voice, data, and routing traffic

- Fiber and broadband access systems — constant, high-volume data exchange

- Modem PCBs — wired and wireless communication devices

- Wireless base stations and backhaul equipment — sustained load

- Satellite communications systems — limited retransmission tolerance

- Radar and signal-processing systems — precise timing and clean high-frequency signals

Telecom Applications We Support

We work with OEMs building communication hardware where performance, uptime, and signal consistency directly affect real-world operation.

- Network infrastructure telecom boards for routing, switching, and traffic management

- Modem PCB assemblies for wired and wireless communication devices

- Communication PCBs supporting high-speed data exchange across broadband and fiber systems

- Wireless and backhaul equipment operating under continuous electrical and thermal load

- Satellite communications hardware requires a clean signal transmission

- Radar and signal-processing systems are dependent on precise timing

Across these applications, telecom boards must perform consistently over long duty cycles. Minor assembly inconsistencies can lead to intermittent failures that are difficult to diagnose after deployment.

How ETEMCO Builds Telecom PCBs for Signal Integrity

ETEMCO focuses on controlled manufacturing and repeatability. We build telecom PCBs to match design intent, manage process variation, and maintain consistency across builds so performance stays predictable as projects move from prototype to production.

SMT and Thru-Hole Assembly for Telecom Boards

Telecom designs are sensitive to placement accuracy, solder consistency, and assembly sequence. We control those variables across runs so builds remain consistent from board to board and lot to lot.

Whether your design uses dense SMT layouts, thru-hole components, or mixed-technology assemblies, our focus stays on repeatability when tolerances matter.

Inspection and Testing for High-Frequency Performance

Signal-related issues often go undetected when visual checks fall short. AOI and X-ray inspection allow us to verify alignment, solder integrity, and hidden features that can contribute to noise or intermittent failures.

Catching these issues early helps prevent downstream troubleshooting, field returns, and late-stage corrective action once systems are deployed.

DFM Collaboration With PCB Designers

When DFM reviews add value, we use them to surface assembly-related risks early. The focus remains on manufacturability without altering the functional circuit design.

This gives engineering teams clearer expectations around yield and production behavior, while helping procurement teams plan timelines and costs with fewer surprises.

Telecom PCB Assembly Within ETEMCO’s Broader Industry Experience

Telecom is one of several complex, performance-driven industries ETEMCO supports. We also build PCBs for medical, industrial, and other mission-critical environments where consistency, documentation, and process control matter.

That

broader industry experience shows up in how we approach telecom PCB assembly. Repeatable processes and disciplined builds aren’t something we switch on for certain projects. They’re already part of how we work every day. Telecom projects benefit from the same structure and rigor, not from a custom workflow that exists only on paper.

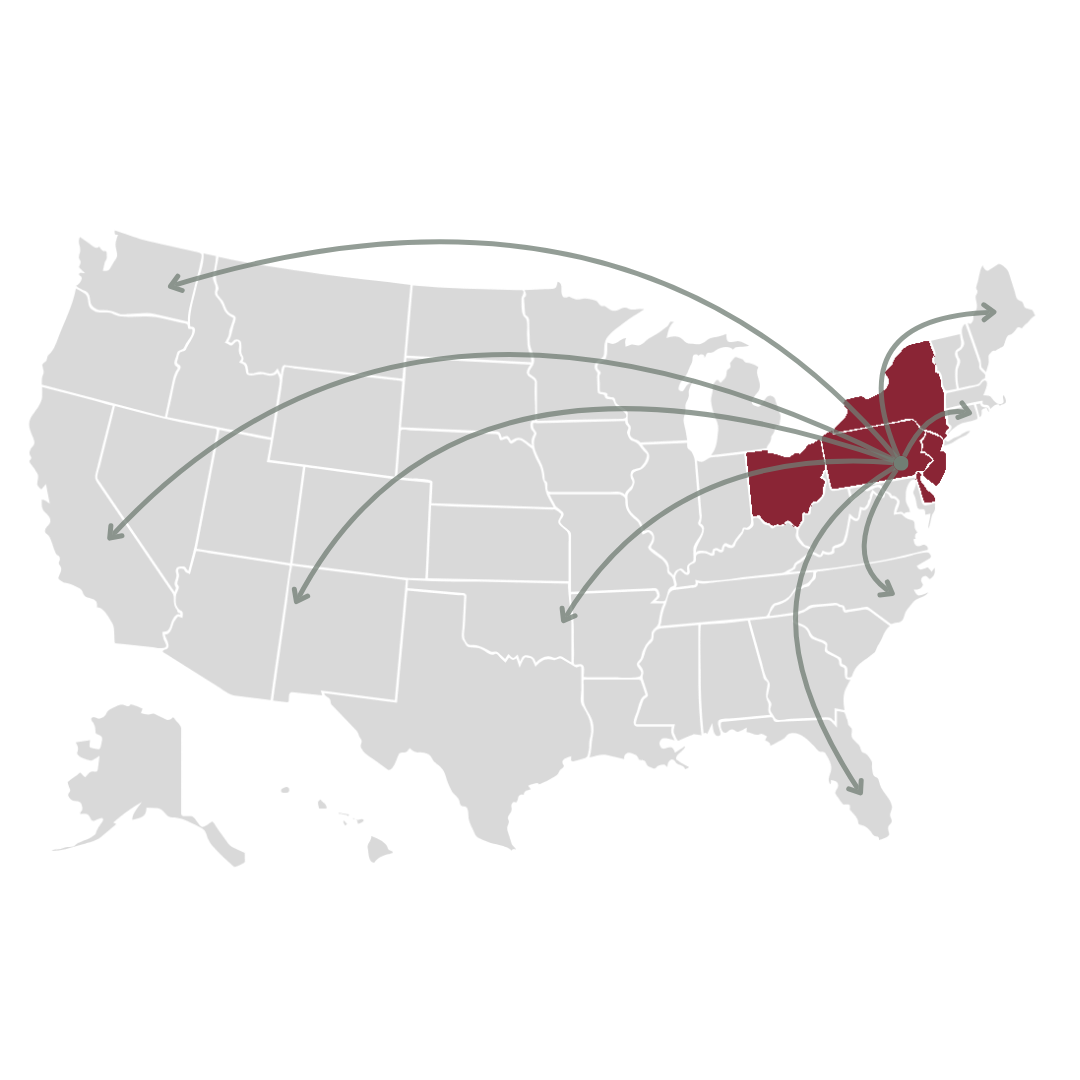

The Regions We Proudly Serve

Pennsylvania • New Jersey • Delaware • Ohio • Nationwide

Telecom OEMs work with ETEMCO because we reduce uncertainty once designs move into production. Our focus stays on execution, communication, and predictable outcomes across builds.

Teams choose ETEMCO for:

- Process discipline that limits variation across runs

- Clear communication when questions or risks surface

- Experience with signal-sensitive electronics

- U.S.-based manufacturing oversight

- Production stability procurement teams can plan around

The result is fewer surprises and telecom boards that behave the same way in the field as they did during qualification.

Why Telecom OEMs Work With ETEMCO

Supporting Telecom OEMs Across the Mid-Atlantic and Nationwide

Working with ETEMCO means fewer follow-ups, fewer escalations, and more confidence once builds are in motion. Our team keeps communication clear, issues visible, and timelines realistic so your job stays focused on forward progress.

If you need telecom PCB assembly that makes projects easier to manage and systems easier to trust, ETEMCO is ready to get started.